What is K-Line ISO 9141 Code and How It Revolutionizes Automotive Diagnostics

Table of Content

- Introduction to Automotive Communication Protocols

- What is the K-Line Protocol?

- ISO 9141 Diagnostics Explained

- How K-Line Communication Works in OBDII Systems

- Comparison: ISO 9141 vs. ISO 14230 (KWP2000)

- Understanding Car Diagnostic Codes via K-Line

- K-Line Error Codes and Troubleshooting

- Practical Applications and Real-World Examples

- Future of K-Line Protocol in Automotive Diagnostics

- Conclusion

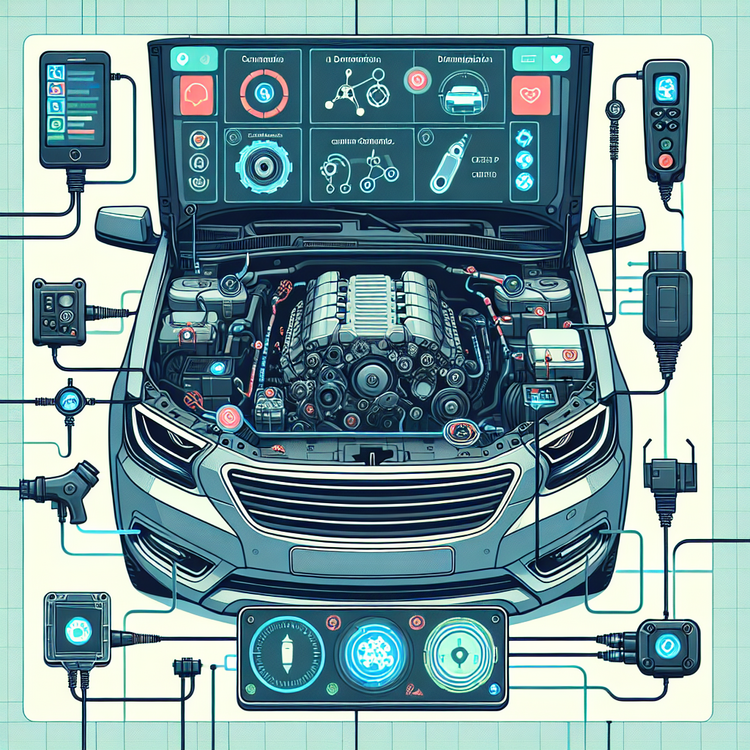

Introduction to Automotive Communication Protocols

Automotive communication protocols are essential technologies that facilitate the exchange of information between different components of a vehicle. These protocols play a crucial role in vehicle diagnostics, allowing for efficient communication during maintenance and repair tasks. By ensuring that various systems can interact seamlessly, automotive communication protocols help mechanics and technicians troubleshoot issues effectively, improving vehicle performance and safety.

One of the key protocols in the automotive sector is the K-Line protocol. This protocol is predominantly used in vehicle diagnostic systems, enabling communication between the car’s onboard computer and diagnostic tools. The K-Line protocol supports various diagnostic functions, including fault code reading and system parameter monitoring. Its simplicity and reliability make it a preferred choice for many automotive manufacturers and service providers.

For more in-depth knowledge on diagnostics, you might be interested in our article on Top Diagnostic Tools for Automotive: 2024 Ultimate Guide.

If you’re looking for professional tools to work with K-Line protocol systems, consider the Perfect Version LED BDM Frame With 4 Probes Mesh For Kess Dimsport K-TAG.

What is the K-Line Protocol?

The K-Line protocol is a communication protocol primarily used in automotive applications for diagnostics and service. It was developed in the early 1990s and has become a fundamental component in the communication systems of many vehicles. This protocol enables various diagnostic tools to communicate with a vehicle’s Electronic Control Unit (ECU), allowing mechanics to read error codes, perform resets, and access vehicle specifications.

K-Line communication operates over a single wire connection, typically utilizing a voltage-based signaling system. When a diagnostic tool is connected to the vehicle, it transmits signals as voltage levels on the K-Line. The ECU receives these signals and responds accordingly. For example, when a diagnostic request is made, the vehicle’s ECU might send back readings of various sensors, making it easier for technicians to identify any issues.

As vehicle technologies have evolved, the K-Line has been integrated with newer protocols like CAN and LIN to facilitate more complex diagnostics and communications, which are vital for modern automotive technology. For a deeper understanding of automotive diagnostics and programming, you may find the Perfect Version LED BDM Frame With 4 Probes Mesh For Kess Dimsport K-TAG useful.

For those looking for advanced diagnostic solutions, the JLR Kit 2025 provides a comprehensive diagnostic tool tailored for Jaguar and Land Rover vehicles.

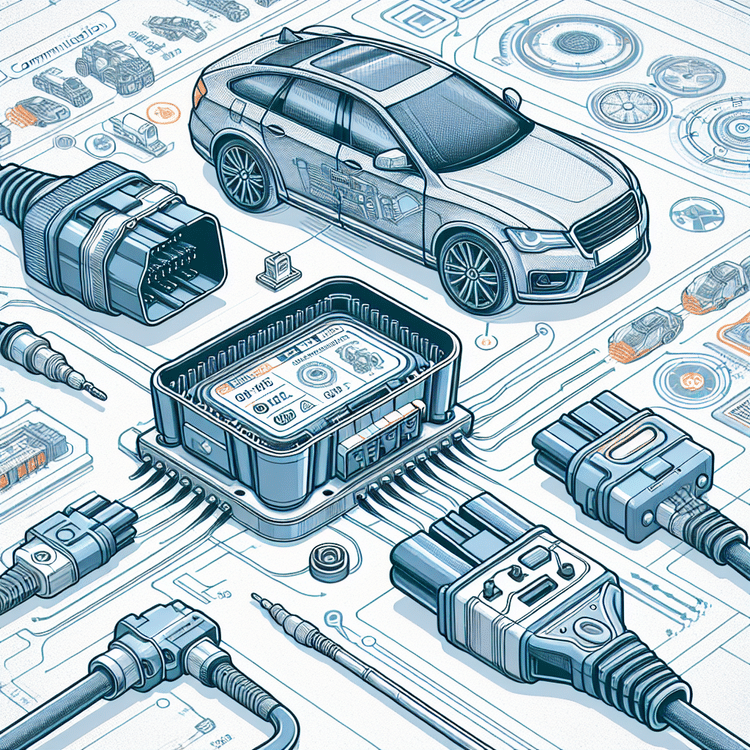

ISO 9141 Diagnostics Explained

The ISO 9141 standard plays a crucial role in automotive diagnostics, particularly with the use of the K-Line protocol. This protocol enables communication between the vehicle’s electronic control units (ECUs) and diagnostic tools, allowing mechanics to retrieve diagnostic trouble codes (DTCs), monitor real-time data, and perform various functions necessary for vehicle maintenance and repair.

ISO 9141 is part of the OBD-II (On-Board Diagnostics II) specification and is primarily used in vehicles manufactured before 2009. It operates using a single wire, the K-Line, for data transmission, which provides a cost-effective solution for diagnostics. By connecting to the K-Line, diagnostic tools can facilitate a wide range of tasks including accessing vehicle specifications, performing emissions checks, and configuring ECUs.

As the automotive industry evolves, standardized diagnostic protocols like ISO 9141 ensure interoperability between vehicles and diagnostic devices. For a broader understanding of the tools that utilize these protocols, check out our article on Top Diagnostic Tools for Automotive: 2024 Ultimate Guide.

Moreover, to enhance your diagnostic capabilities, consider using advanced devices such as the 2024 VNCI MDI2 GM Diagnostic Scanner, which supports multiple protocols including ISO 9141, for comprehensive vehicle diagnostics.

How K-Line Communication Works in OBDII Systems

The OBDII (On-Board Diagnostics II) system plays a crucial role in vehicle diagnostics, allowing mechanics and car owners to monitor vehicle performance and diagnose issues. One of the key communication protocols used in OBDII systems is the K-Line protocol, primarily utilized in older vehicles to facilitate communication between the vehicle’s engine control unit (ECU) and diagnostic tools.

The K-Line communication process works through a single-wire connection, which allows data transfer between the ECU and the diagnostic tool. The protocol operates in half-duplex mode, meaning that data can flow in both directions, but not simultaneously. This is essential for functions such as reading error codes, which help mechanics pinpoint faults in vehicle systems.

For example, when a vehicle experiences an issue, the ECU generates a diagnostic trouble code (DTC). A technician can connect a diagnostic tool to the K-Line, which initiates a communication session. The tool sends a request to the ECU to retrieve the DTCs, and in response, the ECU transmits the relevant car diagnostic codes back to the tool for analysis. This facilitates accurate and timely repairs.

Comparison: ISO 9141 vs. ISO 14230 (KWP2000)

The ISO 9141 and ISO 14230 (also known as KWP2000) protocols are essential standards for automotive communication, each with its unique features and applications.

- ISO 9141:

- Primarily used for OBD-I and early OBD-II vehicles.

- Utilizes a single wire with baud rates typically at 10.4 kbps.

- Advantages include simplicity and compatibility with older vehicles but lacks advanced features.

- ISO 14230 (KWP2000):

- Designed for more modern vehicles with more complex communication requirements.

- Supports higher speeds (up to 10.4 kbps and beyond) and offers features like fast initialization.

- While providing more functionalities, it may be more complex to implement compared to ISO 9141.

In terms of applications, ISO 9141 is often found in older European and Asian vehicles, while ISO 14230 is common in newer vehicles and is used for enhanced diagnostics.

For professionals looking to diagnose vehicles using these protocols, the DA-DoIP VCI device is an excellent tool for multiple protocols including KWP2000.

Additionally, for a comprehensive understanding of automotive diagnostics, refer to our article on OBD1 vs OBD2: What’s the Real Difference?.

Understanding Car Diagnostic Codes via K-Line

The K-Line protocol serves as a vital communication interface for retrieving car diagnostic codes. These codes, often referred to as K-Line error codes, provide crucial insights into a vehicle’s performance and potential issues. To effectively read and interpret diagnostic codes using the K-Line protocol, follow this step-by-step guide:

- Connect the Diagnostic Tool: Use a compatible OBD-II scanner that supports K-Line communication. Plug the device into the vehicle’s OBD-II port.

- Ignite the Engine: Turn on the vehicle’s ignition without starting the engine. This action powers the diagnostic tool and prepares the vehicle’s systems for data retrieval.

- Access the K-Line Protocol: Using the diagnostic tool, select the option to connect via the K-Line protocol. Wait for the tool to establish communication with the vehicle’s ECU (Engine Control Unit).

- Retrieve Diagnostic Codes: Navigate to the section for reading fault codes. The tool will display the active and stored diagnostic codes from the vehicle.

- Interpreting Codes: Each diagnostic code corresponds to specific issues; consult the vehicle’s manual or an online database for definitions and possible solutions.

Understanding these codes allows car owners and mechanics to diagnose and rectify issues effectively.

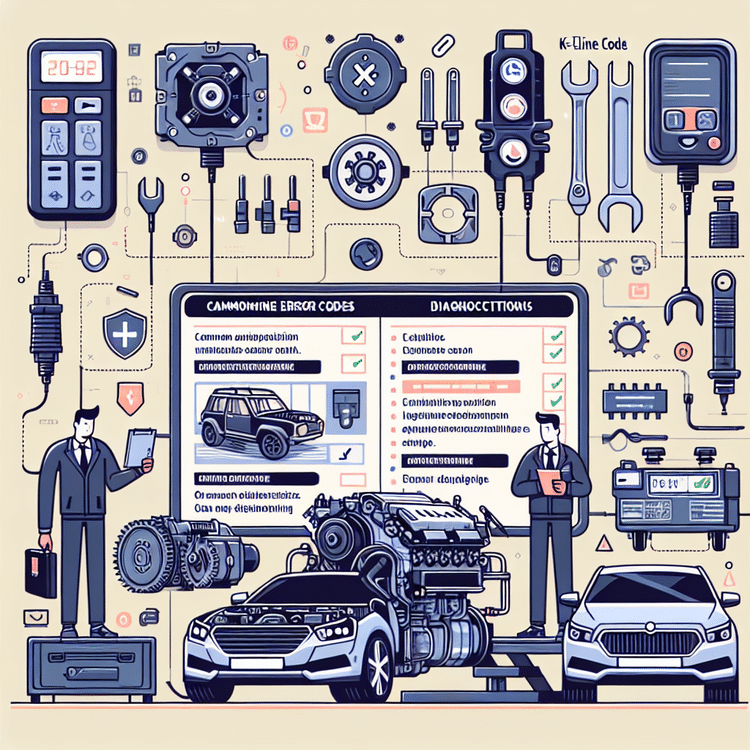

K-Line Error Codes and Troubleshooting

The K-Line protocol is a crucial component in automotive communication, yet it can present challenges in the form of error codes. Here are some common K-Line error codes and their meanings:

- Error Code 10: Communication Error – This indicates that data is not being transmitted correctly between the ECU and the diagnostic tool.

- Error Code 11: Short Circuit – This error suggests there may be a wiring issue, such as a short circuit in the K-Line.

- Error Code 12: No Response – The ECU is not responding to the requests, which might be due to a timeout or broken connection.

Diagnosing K-Line related issues requires some systematic troubleshooting:

- Check Connections: Ensure that all wiring and connectors are securely attached and free from corrosion.

- Use Diagnostic Tools: Leverage tools like the Perfect Version LED BDM Frame to verify communication between the diagnostic tool and the vehicle systems.

- Refer to Error Code References: Utilize resources such as this Comprehensive Volvo Fault Codes List for additional context and solutions related to specific codes.

By systematically checking these areas, mechanics and car owners can effectively troubleshoot and resolve common K-Line errors, ensuring proper vehicle communication.

Practical Applications and Real-World Examples

The K-Line protocol has been a critical component in modern vehicle diagnostics, enabling efficient communication between the vehicle’s ECU and diagnostic tools. One notable application of this protocol is in vehicle repair diagnostics, where it allows mechanics to quickly identify issues and streamline the repair process.

For example, using the JLR Kit 2025, technicians can perform advanced diagnostics on Jaguar and Land Rover vehicles. This kit utilizes the K-Line protocol to connect with the vehicle’s systems, providing detailed fault codes and real-time data, thereby reducing diagnostic time.

Another instance is the use of K-Line in automotive software frameworks. The JLR Software Bundle demonstrates how diagnostic tools leverage K-Line to interface with the vehicle, enabling functionalities ranging from basic diagnostics to full system programming.

The K-Line protocol enhances communication efficiency, making it indispensable for modern vehicle diagnostics.

Overall, the implementation of the K-Line protocol in these tools exemplifies its vital role in improving the accuracy and speed of vehicle diagnostics.

Future of K-Line Protocol in Automotive Diagnostics

The K-Line protocol has long been a cornerstone of automotive diagnostics, primarily utilized for communicating with vehicle Electronic Control Units (ECUs). However, as automotive technologies continue to evolve, the role and implementation of K-Line are also adapting. With the rise of more complex automotive communication protocols, such as CAN and LIN, the K-Line’s relevance remains under examination.

One major trend in the automotive industry is the integration of advanced diagnostics tools that leverage multiple protocols. These tools not only support traditional protocols like K-Line but also modern systems that require more bandwidth and faster data transfer rates. The transition to electric vehicles (EVs) and the increasing complexity of vehicle systems amplify the need for robust communication strategies.

In terms of enhancements, future applications of K-Line may involve better data handling capabilities, allowing for smoother integration with interconnected vehicle systems. Manufacturers are exploring ways to improve K-Line protocol performance, ensuring compliance with emerging regulations while also enriching the diagnostic capabilities available to mechanics and technicians.

Conclusion

The K-Line protocol is crucial in the realm of vehicle diagnostics, representing an essential communication method between the vehicle’s control units and diagnostic tools. Understanding this protocol ensures that mechanics and car owners can effectively troubleshoot their vehicles, minimizing downtime and repair costs. Similarly, the ISO 9141 diagnostics standard provides a foundational framework for diagnostics, particularly for older vehicle models. Together, both protocols are vital tools that enhance diagnostics, ensuring efficient performance and safer driving experiences.

With substantial knowledge about these protocols, readers are encouraged to implement diagnostic practices and utilize tools that support K-Line and ISO 9141 communications for better automotive care. For instance, you can explore the Perfect Version LED BDM Frame to assist in ECU programming, enhancing comprehensive diagnostics.

Moreover, it’s beneficial to stay updated with the latest diagnostic tools. Check out our post on Top Diagnostic Tools for Automotive: 2024 Ultimate Guide to keep your knowledge current and utilize the best technologies available in the market.