The coolant flow system in DD15 engines plays a critical role in maintaining optimal engine performance and preventing potential issues. Understanding how the coolant flows and the components involved is essential for truck owners and operators. In this comprehensive guide, we will delve into the DD15 coolant flow system, its diagram, and provide valuable insights into troubleshooting coolant-related problems.

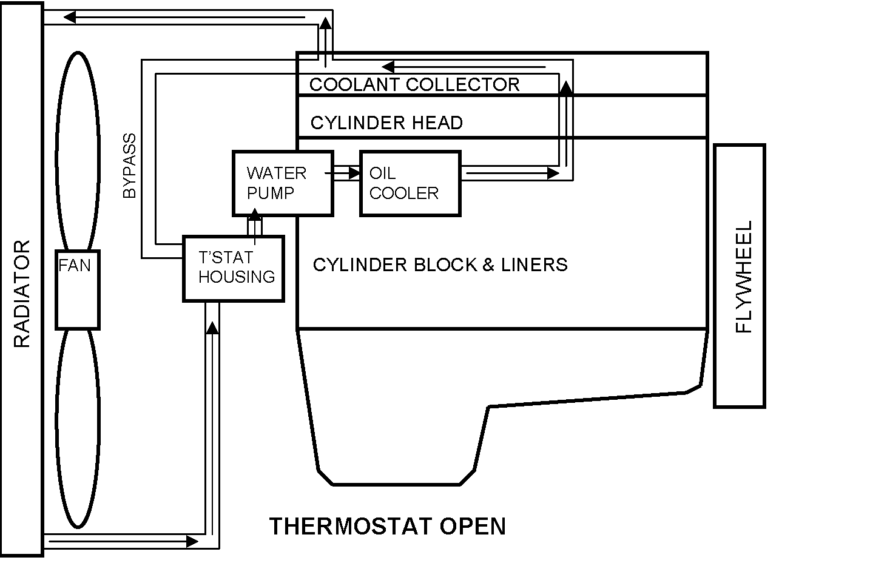

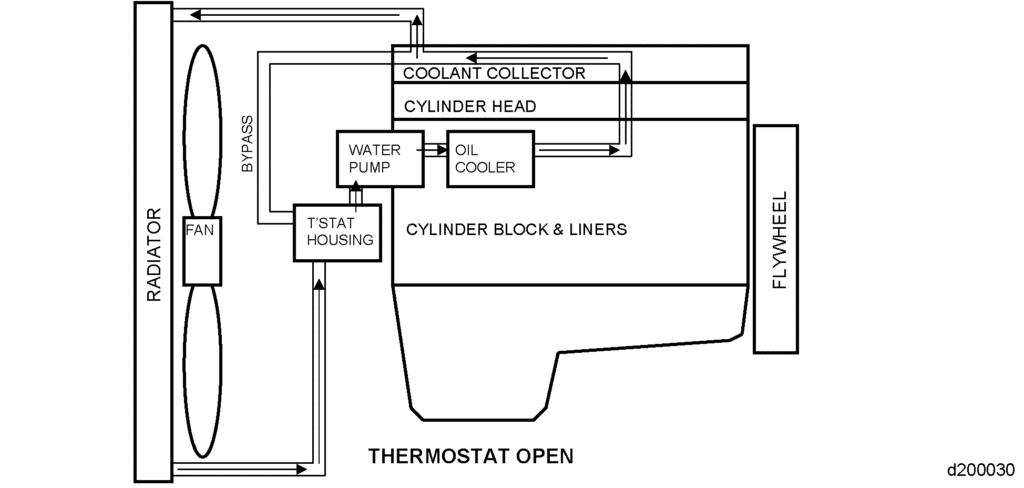

I. Coolant Flow Diagram and Components

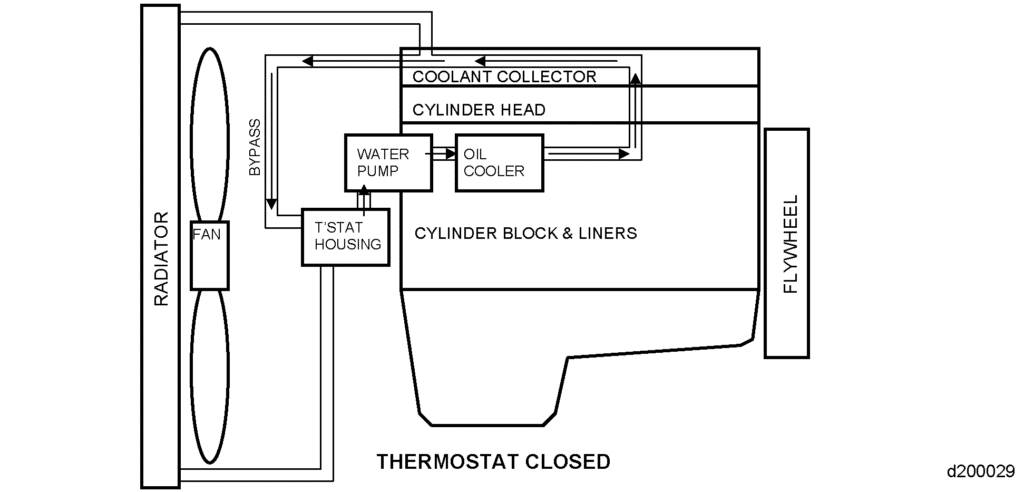

The coolant flow diagram in DD15 engines illustrates the path that coolant takes to ensure proper cooling and engine performance. Let’s explore the essential components involved in the coolant flow system:

Coolant Pump:

The coolant pump, driven by the engine, plays a crucial role in circulating coolant throughout the engine. It ensures that coolant is continuously flowing, allowing heat transfer from hot engine components to the radiator for cooling. The pump’s impeller creates the necessary pressure to maintain optimal coolant flow.

Radiator:

The radiator is a vital component in the coolant flow system. Its primary function is to dissipate heat from the coolant as it passes through its core. The radiator contains a series of tubes and fins that increase the surface area, promoting efficient heat exchange with the surrounding air. By removing excess heat, the radiator helps prevent engine overheating.

Coolant Lines and Hoses:

DD15 Coolant lines and hoses serve as the conduits for transporting coolant between various components of the engine. These pathways ensure that coolant reaches different areas requiring cooling or heat transfer. It’s essential to regularly inspect these lines and hoses for signs of leaks, cracks, or blockages, as they can disrupt coolant flow and lead to engine performance issues.

Thermostat:

The thermostat is a crucial component that helps regulate coolant flow and maintain the optimal operating temperature of the engine. It acts as a valve, controlling the opening and closing of the coolant passages based on the engine’s temperature. When the engine is cold, the thermostat remains closed, allowing the engine to warm up quickly. Once the engine reaches the desired temperature, the thermostat opens, allowing coolant to flow through the radiator for cooling.

Understanding the coolant flow diagram and the role of these components is essential for diagnosing and troubleshooting coolant-related issues. By having a clear picture of how coolant circulates within the engine, technicians can efficiently identify potential problems and take appropriate measures to maintain optimal coolant flow and prevent engine damage.

II. DD15 Coolant-Related Issues and Troubleshooting

Despite the robust design of the coolant flow system, issues can arise that affect coolant circulation and engine performance. Let’s explore some common coolant-related problems and their possible troubleshooting steps:

Coolant Leaks:

Coolant leaks can occur due to damaged hoses, gaskets, or seals within the cooling system. If you notice puddles of coolant under your vehicle or a drop in coolant levels without any apparent reason, it may indicate a leak. Inspect the hoses, connections, radiator, and other components for signs of leakage. Replace or repair any damaged parts and ensure proper tightening of connections to prevent further coolant loss.

Overheating:

Engine overheating can result from coolant circulation problems. A malfunctioning thermostat, a blocked radiator, or a faulty water pump can impede proper coolant flow, leading to excessive heat buildup. If your engine temperature gauge indicates high readings or you observe steam coming from under the hood, immediately stop the vehicle and allow it to cool down. Check for any obstructions in the radiator or coolant passages, inspect the thermostat for proper operation, and ensure the water pump is functioning correctly.

Coolant Contamination:

Contamination of the coolant can occur due to external factors or internal engine issues. Common contaminants include oil, rust, and air. Oil contamination may indicate a leak from the engine oil cooler or a failing head gasket. Rust can occur if the coolant hasn’t been flushed and replaced regularly, leading to corrosion within the system. Air pockets in the coolant can disrupt proper flow and cooling. If you notice any of these issues, consider having the coolant system flushed, replace the coolant, and address any underlying causes of contamination.

Inadequate Coolant Flow:

Insufficient coolant flow can lead to localized hotspots and uneven cooling within the engine. This can result from a restricted radiator, clogged hoses, or a failing water pump. Perform regular inspections and maintenance of the cooling system, including flushing the coolant, to ensure proper flow. If necessary, clean or replace any components impeding coolant circulation.

Coolant System Pressure:

Proper coolant system pressure is vital for maintaining the boiling point of the coolant and preventing overheating. A malfunctioning radiator cap or a leaking pressure relief valve can cause pressure loss. Inspect the radiator cap for any signs of damage or deterioration and replace it if necessary. Ensure that the pressure relief valve is functioning correctly and doesn’t allow excessive pressure buildup.

When troubleshooting coolant-related issues, it’s crucial to follow proper diagnostic procedures and consult the manufacturer’s guidelines. If you’re unsure or unable to resolve the problem, it’s recommended to seek assistance from a qualified technician or service center. Promptly addressing coolant-related issues will help maintain the health and longevity of your engine, ensuring optimal performance and reliability.

Read also: Comprehensive Volvo Fault Codes List: Troubleshooting & Solutions

III. Bypassing DD15 Coolant Flow: Considerations and Risks

Bypassing coolant flow in the engine cooling system is a topic that arises in certain situations, such as dealing with a leaking EGR cooler in a deleted truck. While it may seem like a temporary solution, it’s essential to understand the considerations and risks involved before attempting to bypass coolant flow. Here are some important points to keep in mind:

Impact on Engine Performance:

Bypassing coolant flow means disrupting the intended design and functionality of the cooling system. The coolant plays a crucial role in regulating engine temperature and heat dissipation. By bypassing coolant flow, you may compromise the engine’s ability to cool effectively, leading to increased operating temperatures and potential overheating issues. This can result in accelerated wear and tear on engine components and reduced overall performance.

Potential Engine Damage:

Operating an engine without proper coolant flow can have severe consequences. Without adequate cooling, the engine can experience excessive heat buildup, which can cause damage to internal components, such as the cylinder head, pistons, and valves. Over time, this can lead to costly repairs and engine failure. It’s important to carefully evaluate the risks and potential long-term consequences before bypassing coolant flow.

Warranty and Legal Implications:

Modifying or bypassing the cooling system may void manufacturer warranties and could potentially be in violation of local laws and regulations. It’s crucial to consult with the appropriate authorities and understand the legal implications before making any modifications to your vehicle’s cooling system.

Consider Professional Advice:

Given the complexities and risks involved in bypassing coolant flow, it is highly recommended to seek professional advice from qualified technicians or experts in the field. They can provide valuable insights, assess the specific situation, and guide you towards the most appropriate solution for your vehicle.

Long-Term Solution:

While bypassing coolant flow might offer a temporary workaround for specific issues, it’s important to remember that it is not a long-term solution. Addressing the root cause of the problem and restoring the cooling system to its intended functionality is crucial for the overall health and performance of your vehicle.

Before making any decisions regarding bypassing coolant flow, thoroughly evaluate the risks and consequences. It’s always best to follow manufacturer recommendations and consult professionals who specialize in automotive cooling systems. By taking the right approach, you can ensure the proper operation of your vehicle’s cooling system and maintain its optimal performance and reliability.

IV. Tips for Maintaining Optimal Coolant Flow

To ensure the proper functioning of your vehicle’s cooling system and maintain optimal coolant flow, it’s important to follow regular maintenance practices. Here are some tips to help you maintain optimal coolant flow and prevent potential issues:

Regular Coolant Inspection:

Check the coolant level and condition regularly. Inspect for any signs of coolant leaks, such as puddles under the vehicle or low coolant levels in the reservoir. If you notice any abnormalities, have it inspected by a qualified technician.

Coolant Flush and Replacement:

Follow the manufacturer’s recommended intervals for coolant flush and replacement. Over time, coolant can break down and lose its effectiveness. Flushing the cooling system and replacing the coolant helps remove any contaminants and ensures the proper functioning of the system.

Use the Recommended Coolant Type:

Refer to your vehicle’s owner’s manual to determine the recommended coolant type for your specific model. Using the correct coolant type ensures compatibility with the cooling system components and helps maintain optimal performance.

Inspect Hoses and Connections:

Regularly inspect the coolant hoses and connections for any signs of wear, cracks, or leaks. Damaged hoses can lead to coolant leaks and disrupt the coolant flow. Replace any damaged hoses or connections promptly to prevent further issues.

Maintain Proper Radiator Functionality:

Ensure that the radiator is clean and free from debris or obstructions. A dirty or blocked radiator can hinder proper heat dissipation and affect coolant flow. Regularly clean the radiator fins and ensure proper airflow to maintain optimal cooling performance.

Address Cooling System Issues Promptly:

If you notice any signs of cooling system issues, such as overheating, coolant leaks, or unusual noises, address them promptly. Ignoring such problems can lead to more significant issues and potential engine damage. Seek professional assistance to diagnose and repair any cooling system problems.

Avoid Overloading the Cooling System:

Be mindful of the additional strain on the cooling system when towing heavy loads or driving in extreme weather conditions. Take appropriate measures to manage the engine temperature, such as using auxiliary coolers if necessary.

By following these tips and practicing regular maintenance, you can help ensure optimal coolant flow and the proper functioning of your vehicle’s cooling system. Maintaining a healthy cooling system is essential for preventing overheating, prolonging the life of engine components, and ensuring a reliable and efficient vehicle performance.

Conclusion:

Understanding the DD15 coolant flow system is crucial for truck owners and operators to maintain optimal engine performance and prevent potential issues. By familiarizing yourself with the coolant flow diagram and troubleshooting common coolant problems, you can ensure efficient coolant circulation and extend the longevity of your truck’s engine. Prioritize regular maintenance, coolant level checks, and seek professional assistance when necessary to keep your DD15 engine running smoothly.

Remember, Techroute66.com offers a wide range of OEM diagnostic tools and resources for maintaining and servicing your truck’s coolant system. Explore our website for more information and expert assistance in optimizing your DD15 engine’s coolant flow.

Build custom kits with unmatched precision

Take control of your shop with Techroute66’s Free WMS software – designed for high-end service